Piping

PIPING ENGINEERING AND DESIGN COMPETENCIES

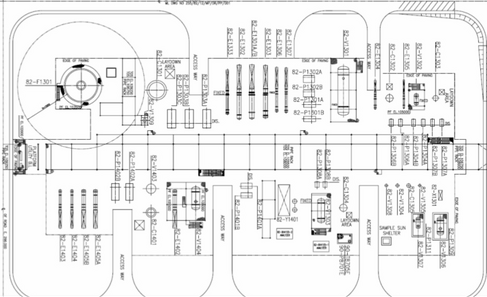

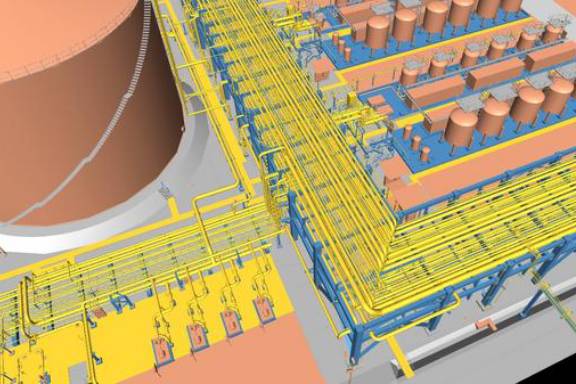

Plant Layout

Development of overall plot plan to identify the space requirement

Equipment Layout

Development of equipment layout based on PFD/ P&ID’s, statutory requirements, etc.

Piping Layout

Development of piping layout based on equipment layout, P&ID’s, vendor data, ergonomics, HFE requirement, etc

Management of interdisciplinary data and avoiding site issues.

Piping Materials

Development of piping specifications, datasheets, MTOs, Material Requisitions, Technical Evaluations, Vendor Document Review, etc.

Piping Stress Analysis and Support Design

Piping stress analysis to meet International and National code requirements using Industry approved software Caesar-II.

Troubleshooting of existing plant piping such as pump misalignments, vibration, etc.

Preparation of IBR approval packages.

Design of pipe supports to meet the various load requirements. Development of datasheet/ specifications of special supports such as spring hangers.

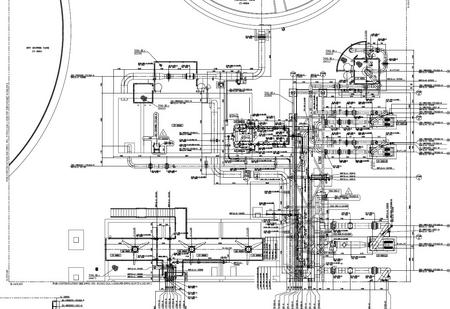

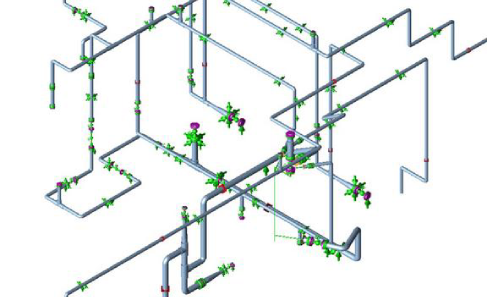

CAD or 3D Modeling

3D modelling using the entire plant as per client requirement.

Model reviews with the client.

Piping isometric generation from a 3D model.

MTO extraction from a 3D model.

Interface management with all disciplines

Constructability review and planning

Piping Materials

Development of piping specifications, datasheets, MTOs, Material Requisitions, Technical Evaluations, Vendor Document Review, etc.